Quality is the cornerstone of our business and underpins everything we do. We consider the best customer to be a repeat customer, and thus do everything in our power to ensure that our customers are satisfied with both the quality of the product and customer service that they receive.

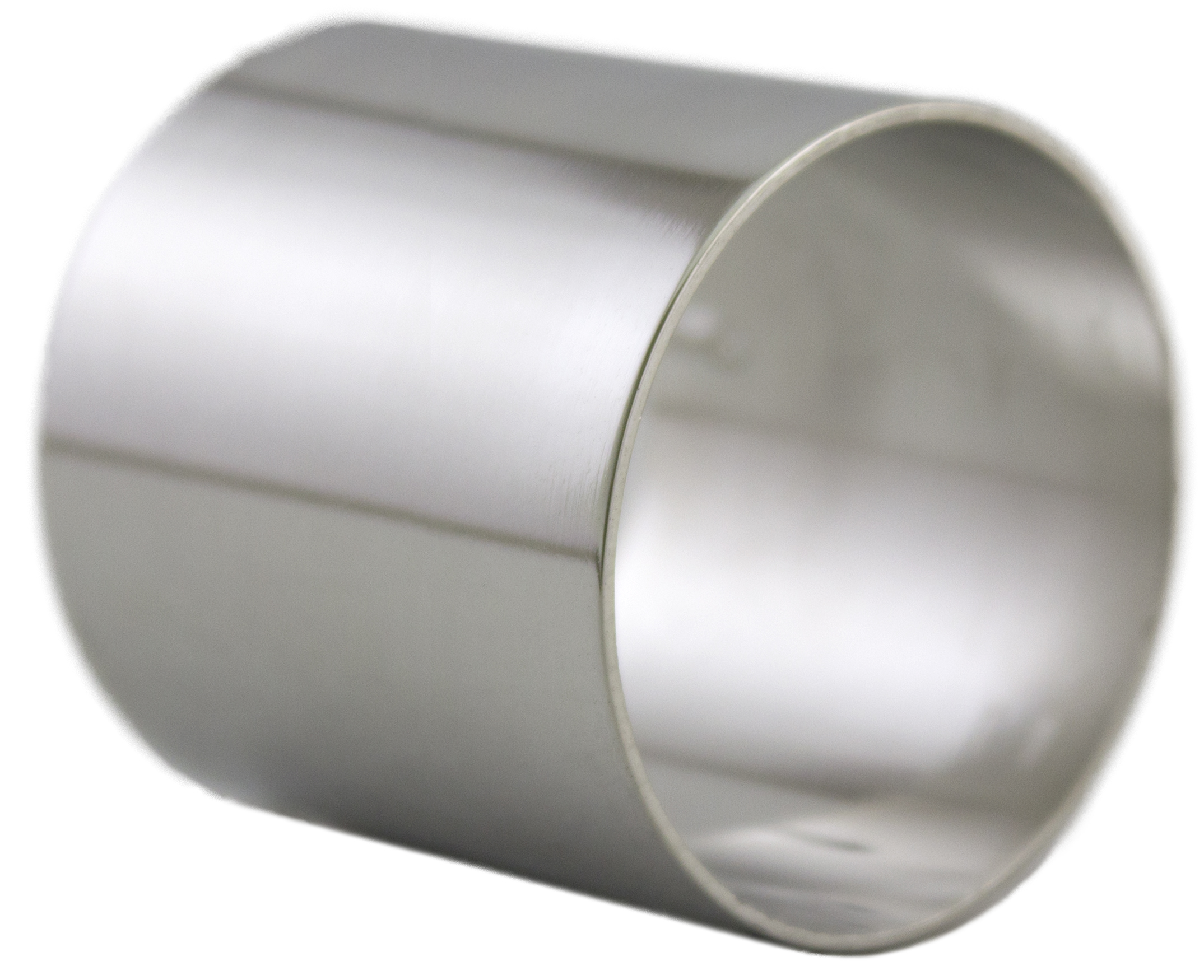

Finishes

Use the dropdown above to quickly browse our finishes.

Silver plating is one of the oldest metal plating processes known to man. First developed in the mid-19th century, silver was plated for decorative purposes on hollowware and flatware, greatly reducing material costs when compared to pure ‘silverware’ counterparts.

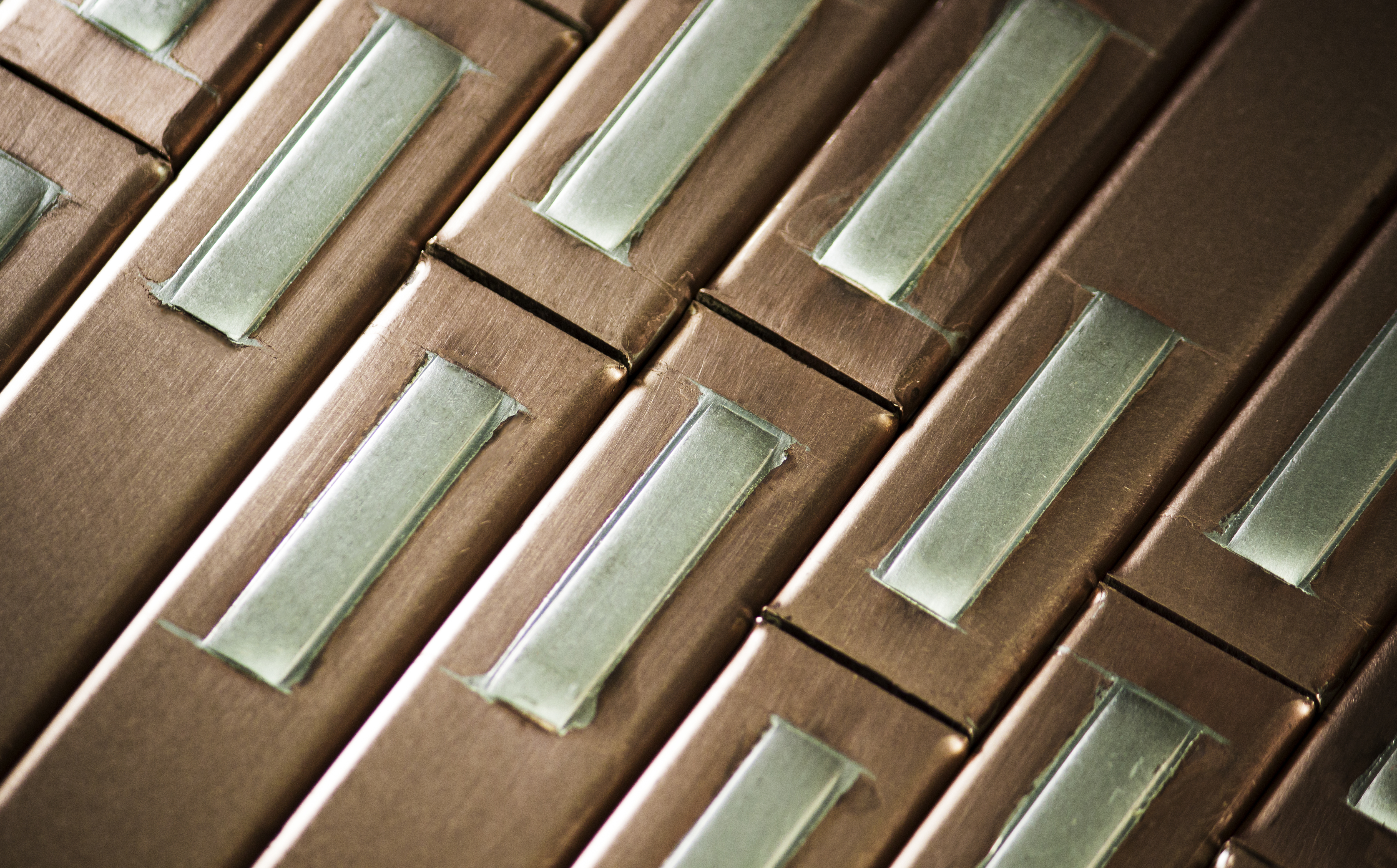

Selective Plating

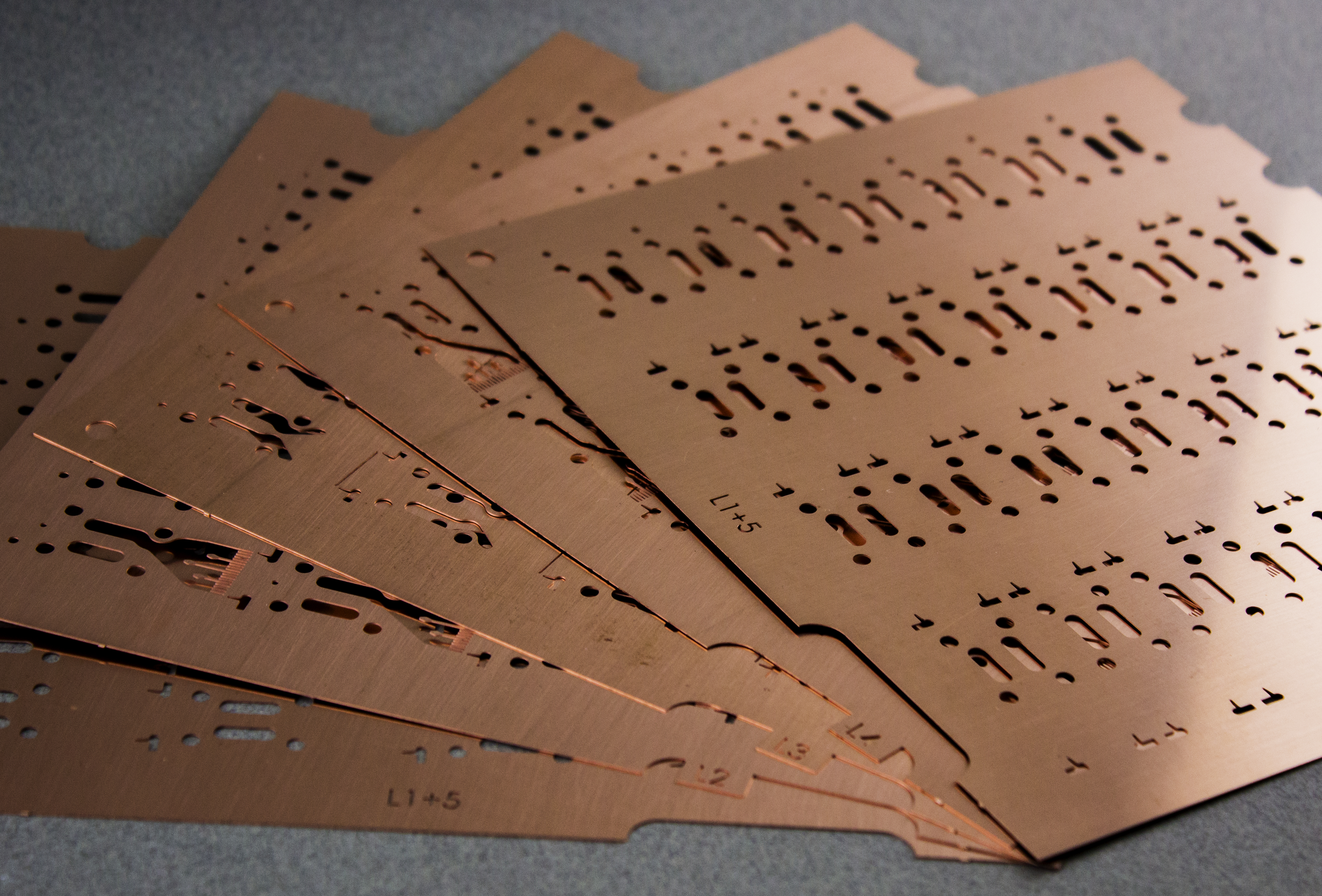

We utilize 40+ years of selective plating experience to develop the perfect mask for each individual part.

Precious Metal Plating

We can tailor our plating methods to maximize a particular characteristic: hardness, solderability, color, reflectivity, corrosion resistance and etc.

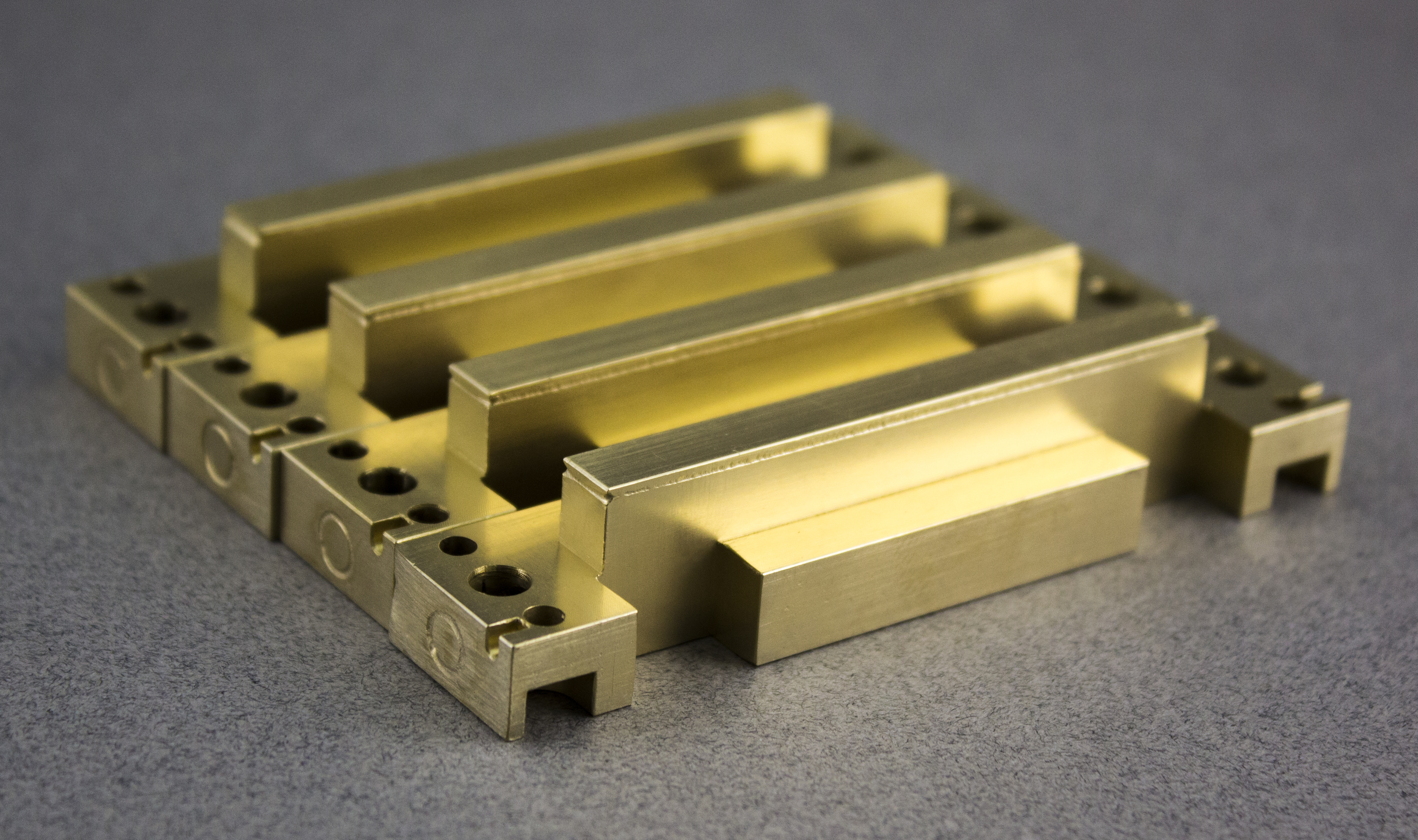

Full-Part Manufactuing

In the ever changing economic landscape of the manufacturing world, let us handle the headaches of sourcing quality parts and reputable suppliers

QUOTES

A Square will be pleased to quote prices for our services in a timely manner. We will work with your parts, drawings, and specifications to determine the best price that we can offer. Our prices are quoted per piece–not by pound, lot, or other vague measure!

A Square also offers precious metal plating with prices pegged to the metal market at the time of shipment. This method offers a cost reduction because it removes the future market estimation from the pricing.